Email Address

agendaconreteltd.gh@gmail.com

Abstract

Ready mixed concrete (RMC) industry,

one of the barebones of construction sector, has its distinctive occupational safety and health (OSH) risks. Employees experience risks that emerge during the fabrication of concrete, as well as its delivery to the construction site. Statistics show that usage and demand of RMC have been increasing along with the number of producers and workers. Unfortunately, adequate OSH measures to meet this rapid growth are not in place even in top RMC producing countries, such as Turkey. Moreover, lack of statistical data and academic research in this sector exacerbates this problem. This study aims to fill this gap by conducting data mining in Turkish Social Security Institution archives and performing univariate frequency and cross tabulation analysis on 71 incidents that RMC truck drivers were involved. Also, investigations and interviews were conducted in seven RMC plants in Turkey and Netherlands with OSH point of view. Based on the results of this research, problem areas were determined such as; cleaning truck mixer/pump is a hazardous activity where operators get injured frequently, and struck by falling objects is a major hazard at RMC industry. Finally, Job Safety Analyses were performed on these areas to suggest mitigation methods.

Keywords: Dust, Ergonomics, Industrial accidents, Occupational health and safety management system, Work environments, Ventilation, Risk management

Introduction

Occupational injuries and illnesses in high risk sectors are considerably prevented with the maturation of the legislation, improvement of technology and development of occupational safety culture. However, this is not always the case particularly in project-based sectors, where risks are constantly changing compared to factory based production. For instance, construction, which is a project-based sector, holds higher ranks in fatal occupational injuries compared to other sectors. In the United States of America (USA) Out of 4,251 worker fatalities in private industry in calendar year 2014, 874 or 20.5% of them were in construction―that is, one in five worker deaths were in construction. This amount holds the first place compared to the other sectors1). The situation is not so different in other countries. Bomel2) notes that in Japan, construction accidents account for 30%–40% of the overall industrial accidents, with the total being 50% in Ireland and 25% in the United Kingdom. In Italy, fatal accidents in the field of construction represent 25% of the total accidents occurring in the industry3). In China, there were an estimated 3,000 construction industry fatalities in 2003 alone4). Globally, construction workers are seemingly three times more likely to be killed and twice as likely to be injured as workers in other occupations. Thus, construction industry needs to be further analyzed for reducing accident rates. Analyses and improvement efforts should include not only construction but also other sub-sectors such as ready mixed concrete industry, prefabricated construction industry, brick plants etc. These sectors should be examined separately because production processes are different from each other, as well as the potential hazards and recommended measures.

Ready Mixed Concrete (RMC) industry, which is one of the most essential sub-sectors of modern construction, is responsible for producing a construction material crucial for constructing engineering structures, such as roads and bridges, homes and high-rises. Combining of fine and coarse aggregates, cement and water is creating this important building material5). Most developed countries prefer to use RMC instead of conventional concrete production because of the advantages of RMC such as: speedy construction through programmed delivery at site, consistency in quality through accurate & computerized control of sand aggregates and water as per mix designs, mechanized operation with consequent economy, minimizing cement wastage due to bulk handling, reducing the labor cost and site supervising cost, proper control and economy in use of raw material resulting in saving of natural resources and reducing project time resulting in savings in all aspects6). Due to the reasons listed above, this product is increasingly being preferred specifically in modern construction. Increasing of RMC production at different countries is shown in Table 17). According to country data, U.S.A. is the top RMC producer in the world, followed by Turkey and Japan.

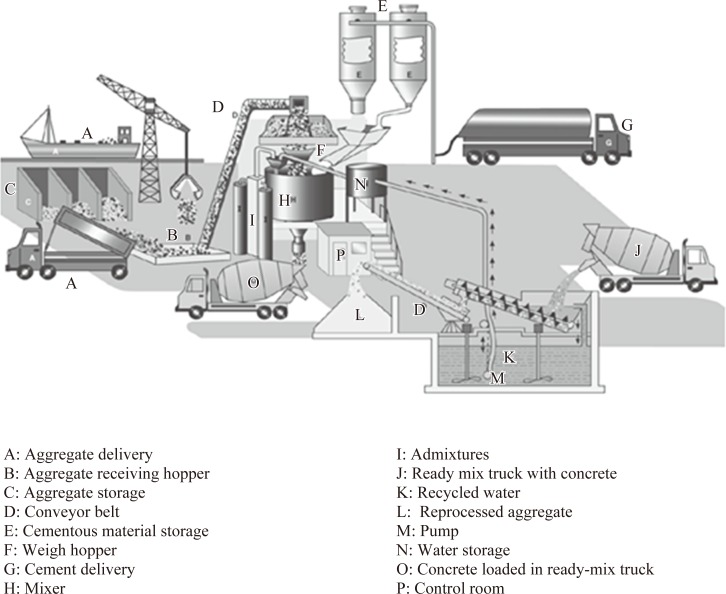

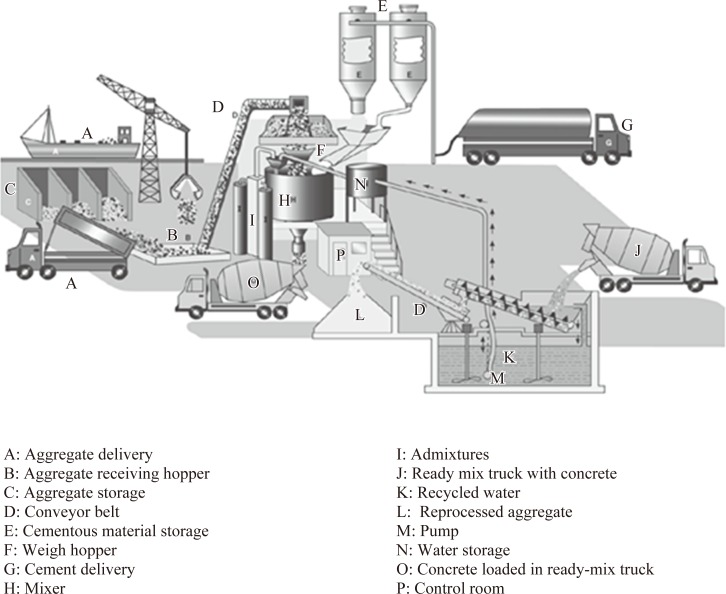

Ready mix concrete plants have many more components to it. In other words, it is the assembly of tools and machines such as mixers, cement batchers, aggregate batchers, conveyors, radial stackers, aggregate bins, cement bins, heaters, chillers and cement silos as shown in Fig. 1. So, operations partially take place in the production area, where RMC is produced and loaded into mixer trucks. The second part of the operations continues outside the production area, where truck mixer transports the materials to a construction site and truck operator assists with the casting process.

Agenda Concrete (Ghana) Ltd, supplier of Ready mix concrete, readymix concrete, ready-mix concrete and Premix Concretes in Ghana. P. O. Box 1187 Accra-Central, Tema - Klagon, Accra | Premix Concrete companies in Ghana | Concrete Industries Ghana